Quantifying Circularity: A Data-Driven Approach to Chip Lifecycle Emissions

In one of the event’s most impactful sessions at Circularity 2025, “From Circular Logistics to Business Innovation” — Cassie Gruber, Director of Sustainability Business Solutions at Jabil, and Kevin Dillman PhD, Solutions Engineer at Makersite, demonstrated how lifecycle intelligence around real-world semiconductor data can enable smarter, more sustainable design choices that balance environmental and economic trade-offs.

Turning Vision into Action: Advancing Circular Manufacturing

To open this masterclass, Gruber and Dillman presented a bold perspective on circular economy strategies, using a case study that compared the environmental and economic impacts of reusable and linear semiconductor chip designs. With sustainability leaders from companies like Amazon, IKEA, and Cisco in attendance, the discussion emphasized integrated, data-driven decision-making as a critical enabler for meeting today’s sustainability standards.

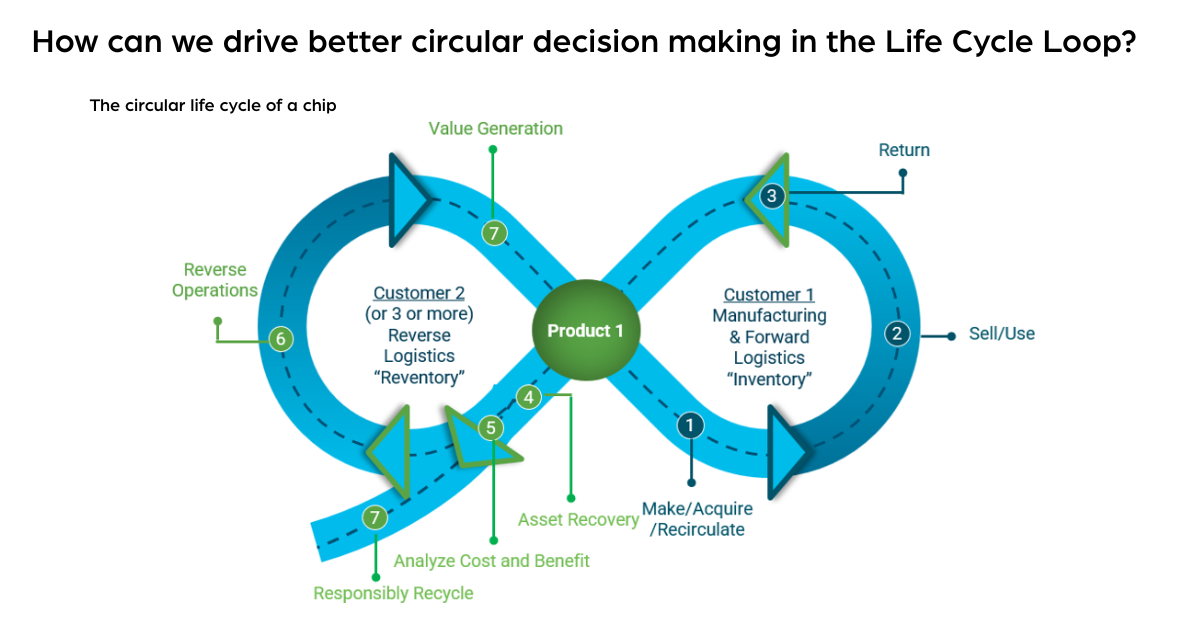

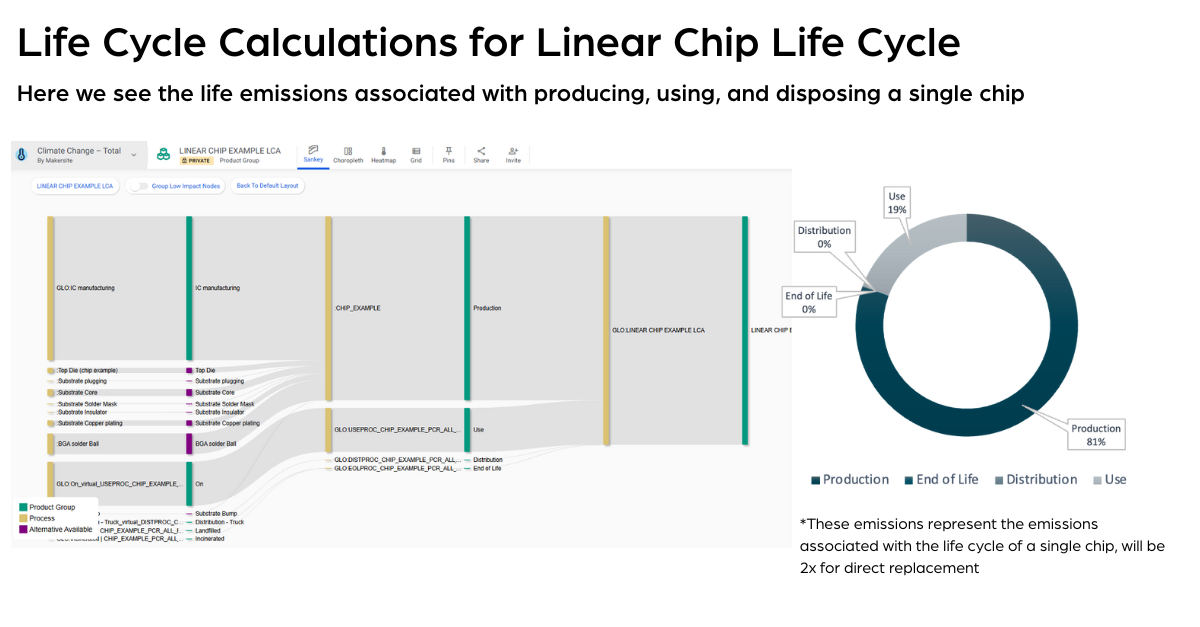

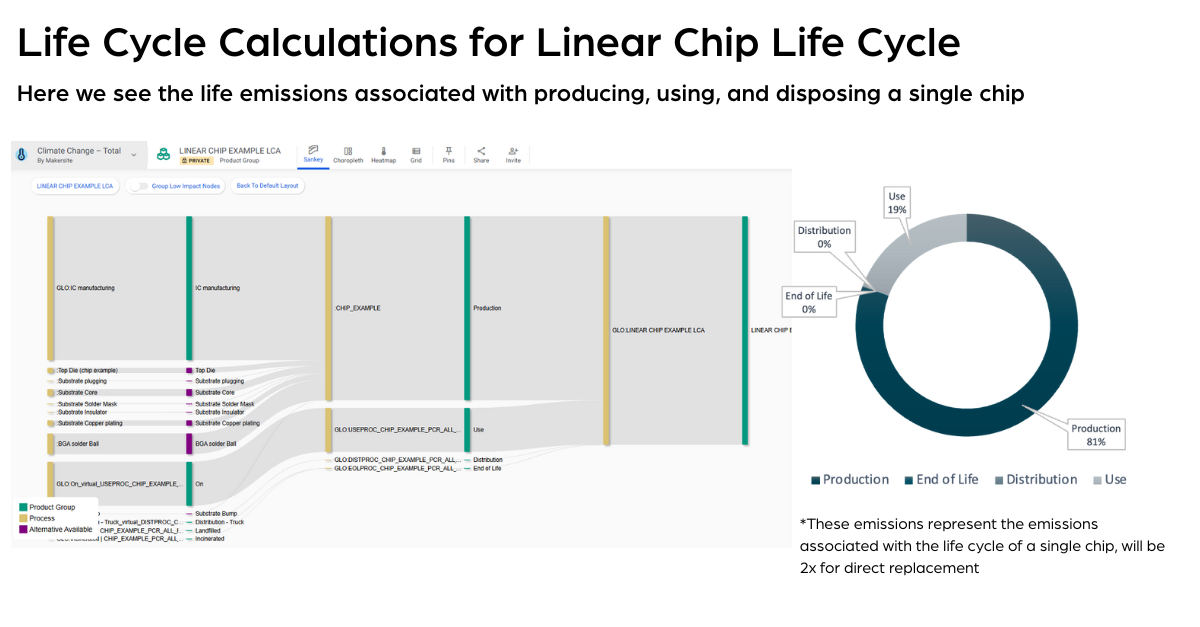

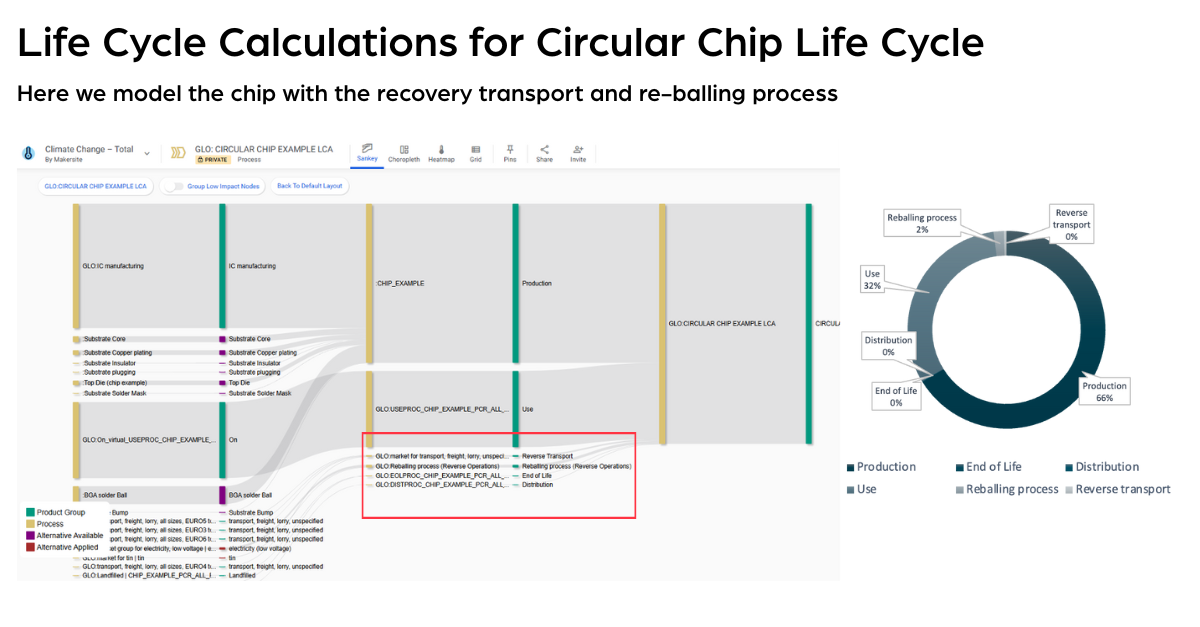

Contrasting scenarios included:

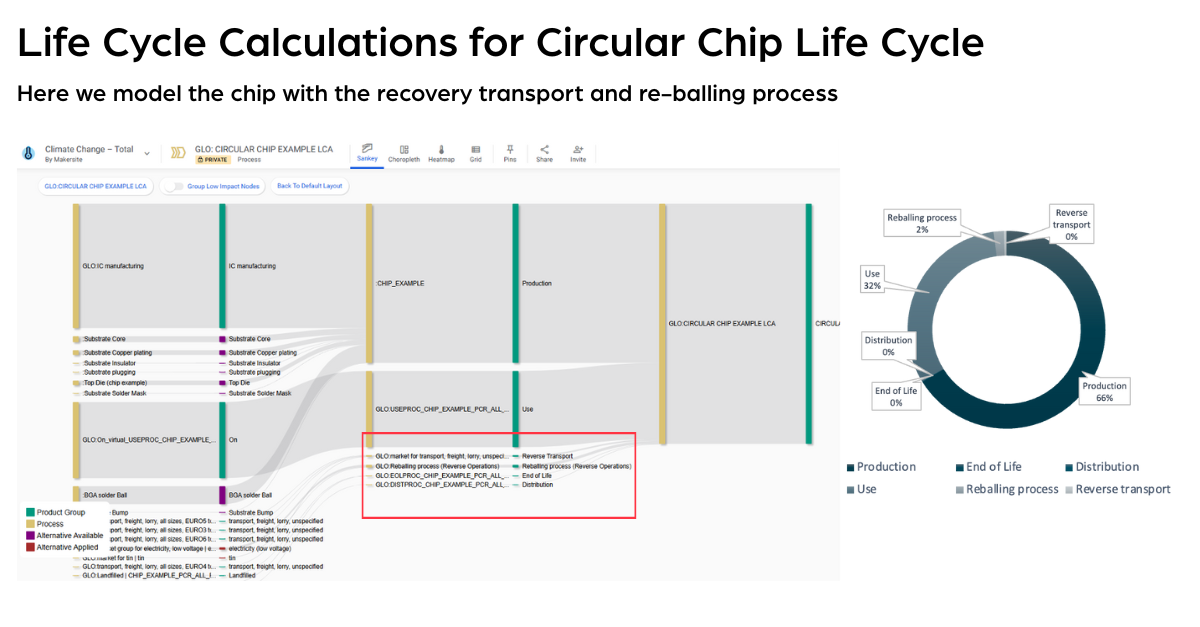

- A linear model, where the chip is manufactured, used, and discarded.

- A circular model, where the chip is recovered, re-balled, and reused.

The circular model demonstrated slightly higher emissions for the reprocessing step (2.36 kg CO₂e vs. 1.94 kg CO₂e for linear disposal), but by extending the lifetime of the initial chip in the circular model, where the linear would now be replaced by a new chip (1.94 x 2 = 3.88 kg CO₂e) the benefits of the circular approach is shown. By eliminating the need to manufacture new chips for future production cycles, the circular process reduces total, system-wide emissions while also drastically minimizing raw material extraction, water usage, and land use.

Circular manufacturing offers a transformative solution for reducing environmental impact and building long-term economic resilience. Forward-thinking companies like Jabil are already operationalizing these principles, turning what was once considered waste into valuable resources through systematic recovery and reuse programs that can also deliver significant cost savings.

Gruber and Dillman’s data-driven example underscores how this model can cut resource consumption, support compliance with evolving sustainability regulations, and drive progress toward a fully circular economy. Businesses adopting these strategies position themselves as sustainability leaders, strengthening their operations against resource scarcity and climate challenges. By embracing circular innovation, companies unlock a powerful pathway to sustainable growth and competitive advantage.

Designing for Circularity: Key Insights from the Session

- Sustainability Requires System Thinking: Achieving a circular economy demands cross-functional collaboration across design, procurement, logistics, and recovery. A unified data foundation is critical to driving these efforts effectively.

- Data-Driven Decisions Over Assumptions: The circular chip example scenario underscores the importance of high-fidelity modeling in evaluating circular strategies. Circular initiatives often lack granular emissions and cost data, making it difficult to assess trade-offs or justify actions internally. Digital tools that enable engineers and sustainability teams to quantify carbon impacts and material costs at the component level provide the analytical rigor needed to support data-backed circularity decisions.

- Leadership Focuses on Actionable Insights: The strong participation of executives and senior managers in the session underscores growing C-level commitment to sustainable innovation and responsible driven business models.

- Scalable Platforms Are the New Standard: Fragmented tools fall short in today’s complex landscape, creating new data silos and preventing transparency. Forward-thinking sustainability leaders are turning to scalable platforms and digital tools to seamlessly integrate sustainability, cost efficiency, and product compliance into their operations.

Driving Circularity with Actionable Product Intelligence

As manufacturers push toward circular economy goals, decision-makers are increasingly turning to digital tools that provide high-resolution insights across the product lifecycle. These platforms are enabling sustainability, procurement, and design teams to move beyond assumptions by modeling the environmental and economic implications of circular strategies in real time.

By bringing together lifecycle data, cost metrics, and supply chain considerations, these tools support:

- Comparative analysis of linear vs. circular models

- Identification of trade-offs across environmental categories

- Alignment across teams through shared, data-driven insight.

In a rapidly shifting regulatory and market landscape, the ability to simulate design choices at scale — grounded in real-world data — is essential. Organizations that invest in this type of intelligence aren’t just improving products; they’re reshaping how sustainability is operationalized across the enterprise.

Turning Circular Strategies into Scalable Impact

For manufacturers, achieving sustainability success requires integrating data-driven insights and lifecycle thinking into design and procurement processes. This approach empowers teams to scale effective strategies such as reducing product carbon footprints, ensuring regulatory compliance, and driving operational efficiencies. With data and cross-functional alignment at the core, circularity evolves from a lofty goal to a measurable competitive advantage, positioning businesses as leaders in innovation and sustainability.

Kevin Dillman PhD., Solutions Engineer at Makersite | Rich Bulger, Partner at Capital Growth Partners | Cassie Gruber, Director of Sustainability Business Solutions at Jabil | Peter C. Evans PhD., Senior Advisor at Capital Growth Partners | Deborah Dull, Managing Partner at Trillium Digital Services