Overview

After 18 February 2027, every EV, LMT, and industrial battery in the EU will be dead on arrival without a digital battery passport. That’s the main change brought by the new EU Batteries Regulation, which entered into force on 17 August 2023. Battery producers who fail to comply might see a revenue drop. While there’s still time to avoid this financial risk, you’ve got to act right now. Doing it on your own could be overwhelming, so we’ve outlined a series of steps you should take to ensure compliance.

1. Drop Last-Min Compliance Mindset

Get your battery digital passport ready sooner rather than later. This is not a mere compliance exercise. An early adoption of this tool will give you a competitive edge. Based on the study conducted by the Battery Pass consortium, a digital passport could reduce the need for technical tests, thus driving down procurement costs for independent operators by up to 10%. Furthermore, thanks to the improved recycling rate (up to 2%), the battery e-passport will reduce pre-processing and post-treatment expenses for recyclers by up to 20%. To add to that, better recycling implies a lower amount of primary materials used. This then translates into up to 1300 kt of CO2eq that could be saved annually by 2045.

On the other hand, a compliance delay could seriously hurt your business. That’s what happened to Meta, which was fined €1.2 billion by the Irish Data Protection Commission for transferring EU users’ personal data to the US without meeting GDPR requirements.

2. Engage Your Suppliers

Let’s put it bluntly. If you don’t have supply chain data, your battery passport won’t get stamped. That’s why it’s paramount to liaise with your suppliers. Reach out to them and shed light on how this regulation will affect their business. Explain to them the benefits of sharing data as this will increase trust. Building a partnership around transparency is also critical to draft the due diligence policies for the sourcing of critical raw materials which are required by the regulation.

3. Implement An Efficient Data Management System

Creating and managing a battery digital passport means collecting an enormous amount of data from multiple sources. And that’s the hardest job nobody is prepared for. Nobody, except specialised companies like Makersite. We leverage an AI-enabled technology that lets you automatically consolidate all your information into a centralized platform in no time.

Our system also allows you to perform a lifecycle analysis (LCA) to have an accurate estimate of your battery’s carbon footprint, which is one of the passport’s key attributes. However, don’t expect an accurate LCA if you don’t feed accurate data to the system. That means you should gather detailed information on raw material, energy & water consumption, and waste production associated with each stage of the product’s life cycle.

Moreover, make sure to tap into a supply chain mapping feature to assess your supplier practice and spot inefficiencies. That’s what Makersite has done for an international cosmetic company. Combining an automated multi-tier mapping of their value chain with AI-powered suggestions, we allowed them to achieve a more sustainable and cost-effective sourcing in less time. Our case study shows how value chain diligence can flip from a cost center into a margin protector.

4. Governance

AI won’t solve all your problems. You need to invest in human resources as well. For instance, it might be wise to rely on software experts who can help you understand your data to make more informed decisions.

Another useful strategy would be to appoint internal compliance personnel or create cross-functional taskforces (R&D, supply chain, legal) if not already in place. Additionally, it would be helpful to implement robust supply chain audit and reporting processes to promote transparency.

Is Your Battery Affected By The Regulation?

This rule applies to the following types of batteries:

- portable batteries;

- starting, lighting and ignition batteries (SLI batteries);

- light means of transport batteries (LMT batteries);

- electric vehicle (EV) batteries and industrial batteries;

- batteries that are incorporated or designed to be incorporated into or added to products.

The Battery Passport

The regulation’s key implication is the attachment of an electronic record, a.k.a. battery passport, to each LMT battery, each industrial battery with a capacity greater than 2 kWh and each EV battery. Manufacturers should have the battery passport ready by 18 February 2027.

What Information Should The Passport Contain?

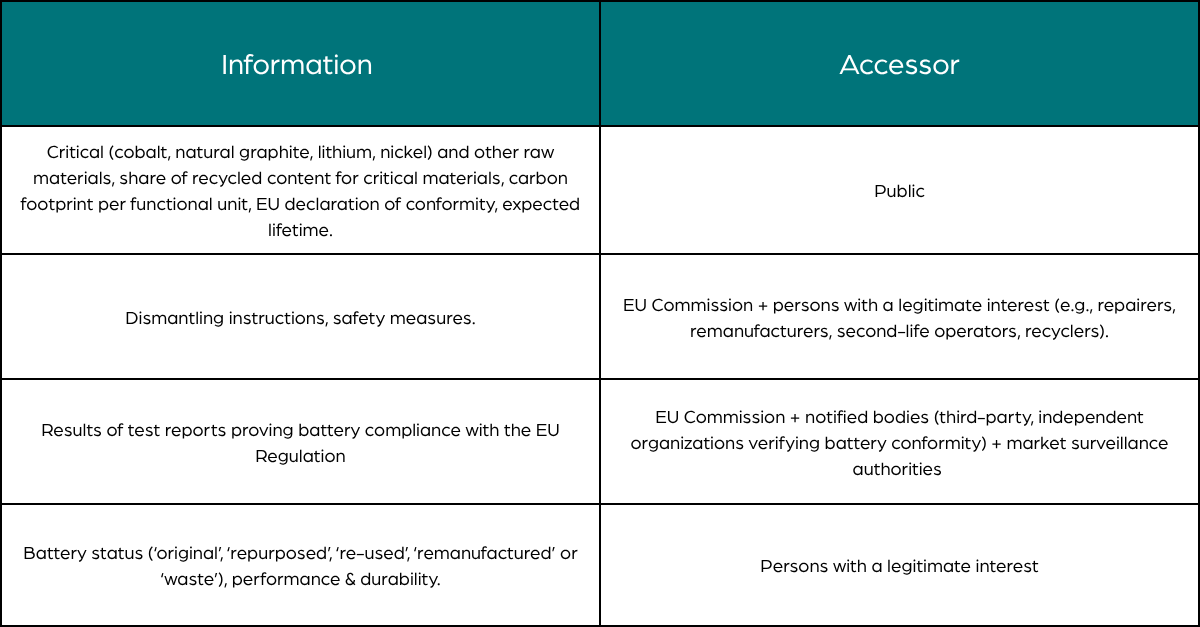

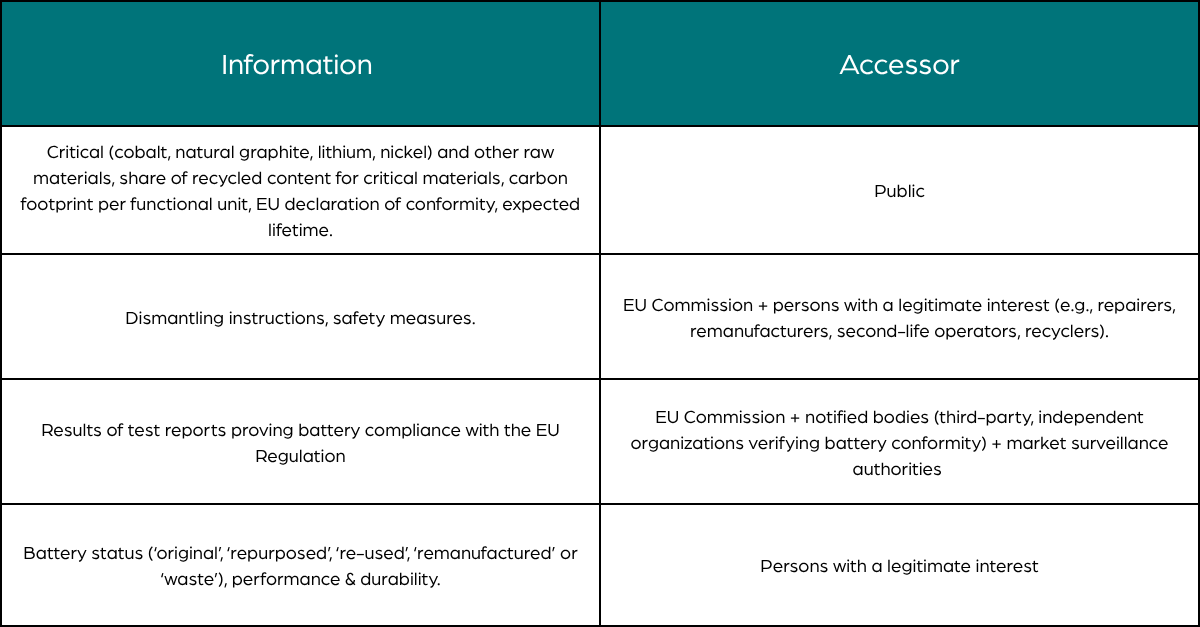

As reported in the Appendix, the information contained in the battery digital passport are classified according to who should access it.

Technical & Operational Obligations For Manufacturers

Besides collecting a lot of credible data and storing it for 10 years, when compiling a battery passport manufacturers will also have to meet a series of technical and operational requirements.

- Due diligence: Manufacturers must adopt and communicate due diligence policies for the supply of critical raw materials (i.e., cobalt, natural graphite, lithium, nickel) and its associated risks. These policies should be in line with internationally recognized standards such as the OECD Due Diligence Guidelines and the UN Guiding Principles on Business and Human Rights.

- QR Code: This is the unique identifier that manufacturers will have to attribute to each of their batteries to ensure access to the digital passport. The QR code should respect the guidelines of ISO/IEC Standard 18004:2015.

- Interoperability: The battery passport will have to be interoperable with other digital passports required by the EU (e.g., the Digital Product Passport (DPP) introduced by the Ecodesign for Sustainable Products Regulation (ESPR)). All information should be based on open standards and transferable through an open interoperable data exchange network.

- Data Access: Manufacturers should have a data system allowing them to attribute different types of access rights as per the Regulation (see also Appendix).

Regulation Uncertainties

After going through the EU Batteries Regulation, some grey areas remain. First of all, some level of confusion still lies on access rights. The rule leaves it to the EU Commission to elucidate this aspect through the issue of implementing acts. These secondary legislations should clarify which stakeholders (e.g. persons with legitimate interest, third-party organisations, etc.) are entitled to access which datasets.

The Commission will have to publish other acts to give further guidance on the following too:

- methodologies for calculating carbon footprint;

- minimum values for electrochemical performance;

- share of recycled content for non-critical battery materials;

- harmonised formats for data reporting (e.g., real-time or static information?) and labelling.

Finally, while the regulation says that the digital passport should be interoperable with other similar EU frameworks (e.g., DPP), it doesn’t mention anything on non-EU systems. This could pose a double reporting issue for global manufacturers.

What Should You Do Now To Prepare?

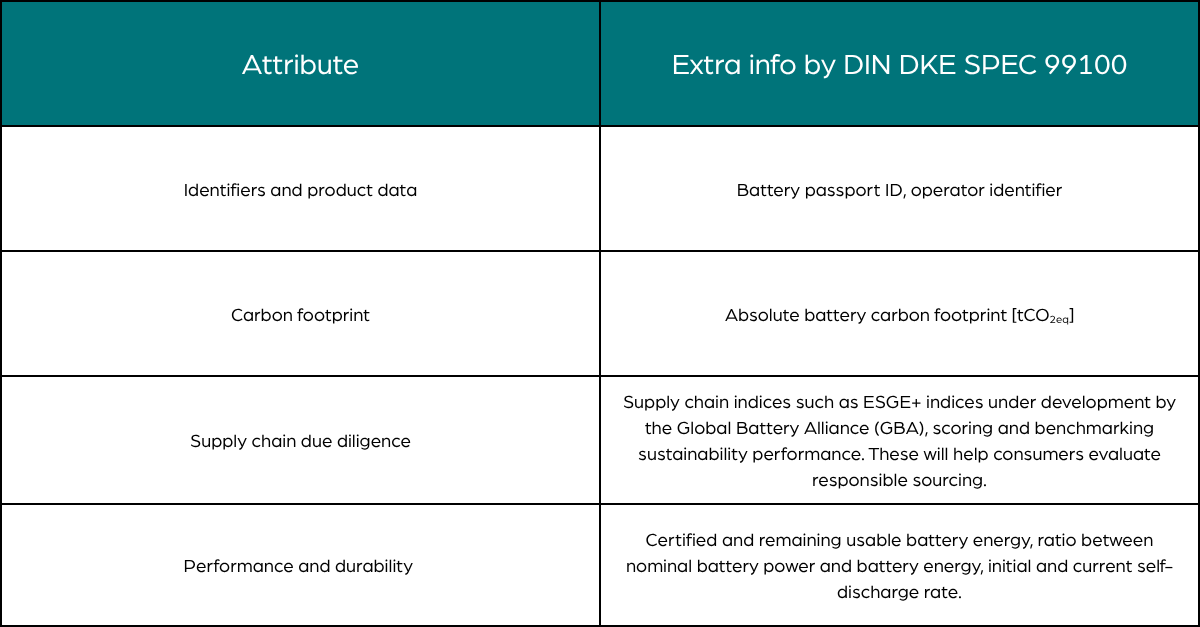

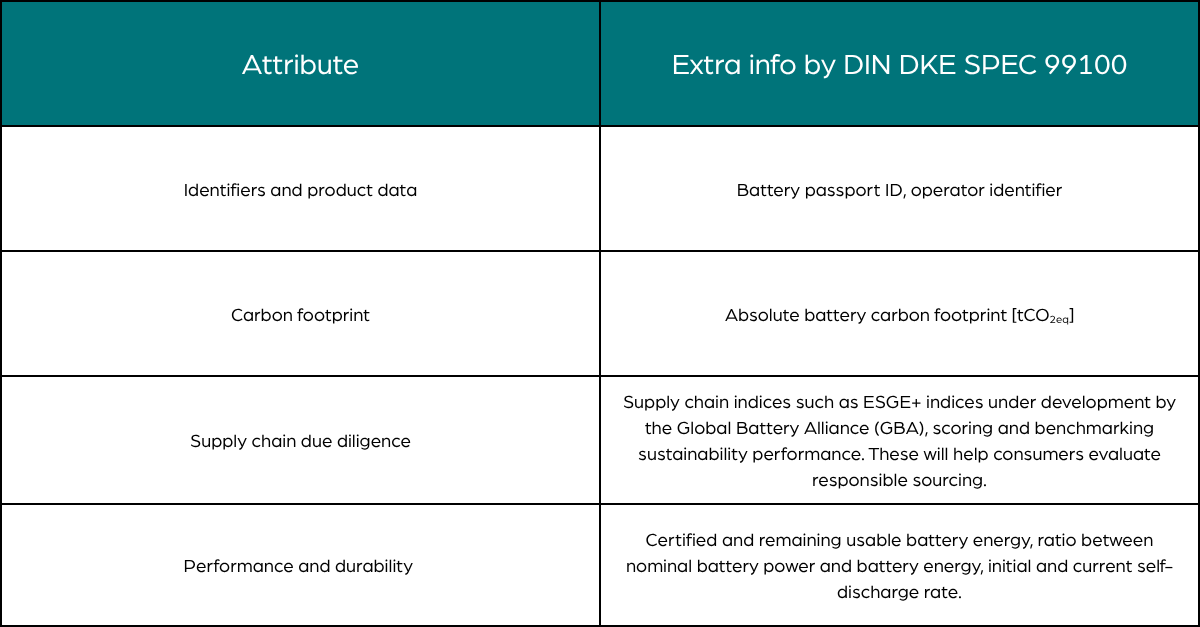

Aside from familiarising with the EU Battery Regulation, manufacturers can go beyond that by checking out the DIN-DKE SPEC 99100. Based on the Battery Passport Content Guidance, this document provides battery producers with more details and recommendations on each data attribute to embed in the digital passport.

Conclusions

Complying with the EU Batteries Regulation will require way more than plugging any data into any AI tool. To begin with, gathering good data about your battery implies engaging suppliers and finding out as many details as possible on critical and other raw materials. Moreover, data interpretation can be a time-consuming task without expert oversight. Although AI can help speed things up, you still need human validation to assure data integrity. Manufacturers who master high-quality product data now will cut costs, avoid double reporting, and be first to market. That’s the advantage Makersite is building for its customers.

Appendix

Still Some Doubts? Let’s Clarify Them

What Happens If My Company Isn’t Ready For The EU Battery Passport By February 2027?

Without a valid passport, affected batteries can’t be sold in the EU. That means blocked market access, potential fines, and losing out to competitors who prepared early. The biggest bottleneck is neither the QR code nor the reporting templates — it’s the supply chain and lifecycle data that companies often don’t have in usable form.

👉 This is where Makersite helps: consolidating supplier and product data into a live, compliant passport.

Isn’t The Battery Passport Just A Compliance Exercise?

No. The regulation is designed to push transparency and sustainability across the value chain. Companies that treat it only as a compliance task will incur costs; instead, companies that use the passport as a data backbone can reduce procurement costs, cut CO₂, and strengthen supplier resilience.

👉 Makersite turns compliance data into a business advantage by linking it to cost, carbon, and risk models.

How Is The Battery Passport Different From The Digital Product Passport (DPP)?

The battery passport is the first sector-specific implementation of the EU’s broader push for DPPs. Both share the same goal: live, interoperable product data. If you solve for the battery passport correctly, you’ll be positioned for future DPP rollouts across other product categories.

👉 Makersite’s platform is built for both — future-proofing your compliance investments.

What Type Of Data Is Hardest To Gather For The Passport?

Supply chain data on critical raw materials, recycled content, and carbon footprint. Most manufacturers don’t have visibility past Tier 1 suppliers, making this the single biggest challenge.

👉 Makersite uses AI + supply chain mapping to fill gaps, validate supplier inputs, and model missing data.

Why Can’t We Just Wait Until The EU Clarifies The Regulation’s Grey Areas?

Because building the data infrastructure and supplier collaboration needed for a passport takes years. If you wait for the EU’s secondary acts, you’ll stay behind.

👉 Makersite allows you to start building compliant passports today, while staying adaptable to regulatory updates.

How Can AI Be Used To Map Supply Chains Or Enrich Missing Data For The Battery Passport?

AI can accelerate the mapping of multi-tier supply chains by consolidating information from public databases, supplier disclosures, and proprietary datasets. It can also enrich missing attributes (such as carbon footprint or recycled content) by benchmarking against process- and material-specific models.

But AI is only as good as the data and expertise behind it. For compliance-grade outputs, AI must be trained on high-quality supply chain data and guided by experts who understand materials, processes, and regulatory standards. Large Language Models (LLMs) aren’t suitable here — this is about structured, verifiable data that stands up to audits.

👉 Makersite combines AI-driven automation with expert-validated data and robust databases, ensuring your battery passport is accurate, compliant, and defensible.